Serious cut, fast results - Lake Country’s Microfiber HDO Cutting Pad is built to eliminate heavy defects with consistency and control.

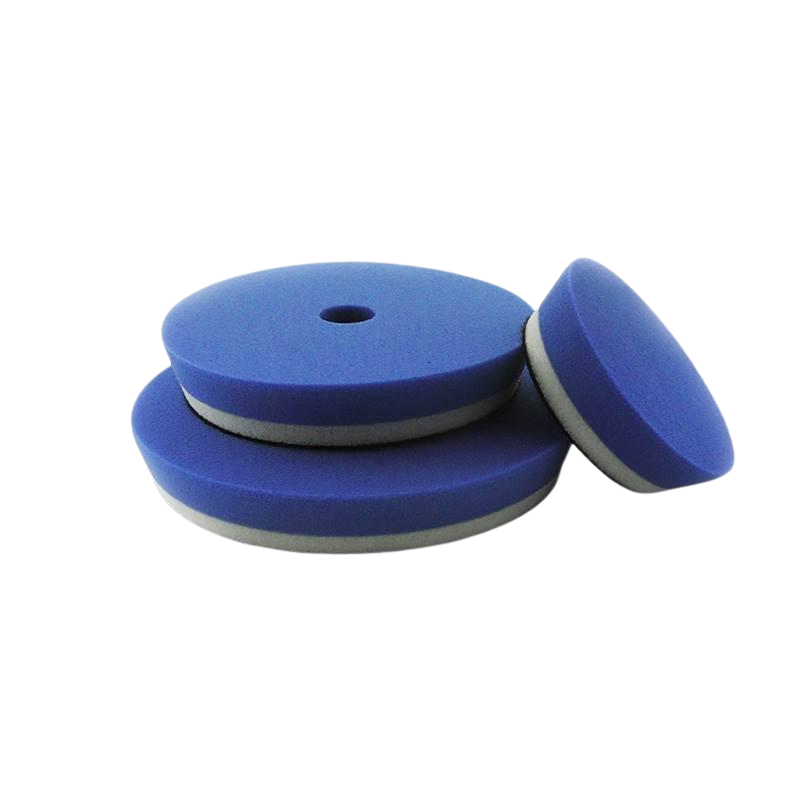

The Lake Country Microfiber HDO Cutting Pad is a high-performance microfiber cutting pad designed for medium to heavy correction work on all paint systems. Using thousands of premium abrasive fibre strands, this pad levels sanding marks, swirl damage, and oxidation with ease - while maintaining a surprisingly refined finish for a pad in its class.

The HDO version includes a ventilated centre cavity, which helps regulate heat and extend pad life during longer correction sets. This centre hole, paired with a durable foam interface, improves performance on dual action polishers by reducing matting, lowering pad temps, and keeping cut levels consistent across multiple passes.

Whether you're working in heat or humidity, this cutting pad resists clogging, spurring, and premature breakdown - making it one of the most durable and balanced microfiber pads on the market.

Features

-

Advanced Microfiber Tech: Densely packed, plush fibres act as abrasives to quickly remove defects while resisting matting.

- Foam Interface for DA: Improves durability and machine feel on orbital polishers - stays balanced even under pressure.

- Ventilated Centre Cooling: Reduces heat build-up and pad fatigue, especially during longer correction cycles.

- Consistent High Cut: Ideal for medium-heavy defect removal including sanding marks, oxidation, and water spots.

-

All-Paint Compatibility: Works effectively across hard, medium, or softer clears in any climate condition.